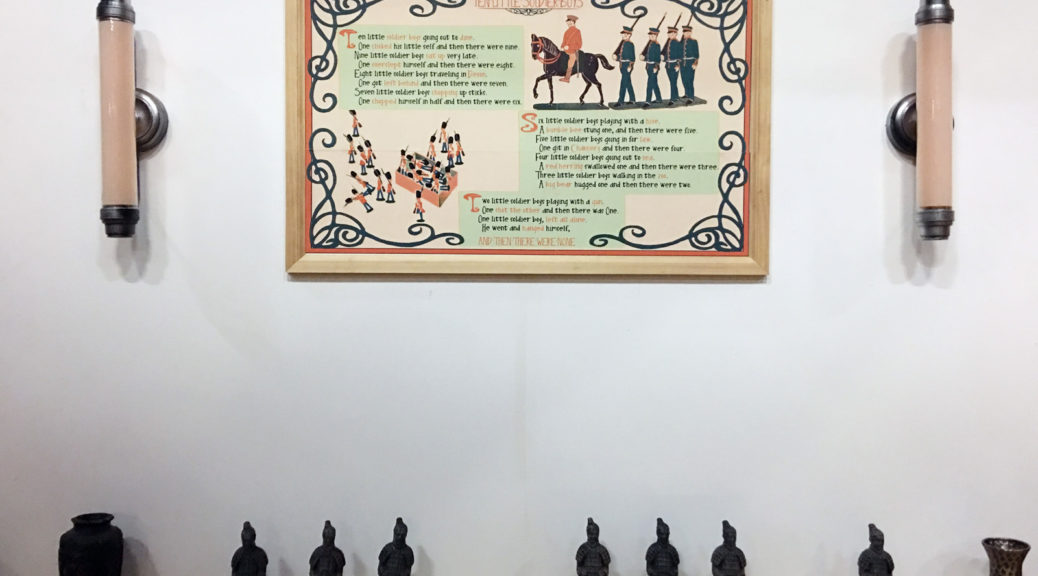

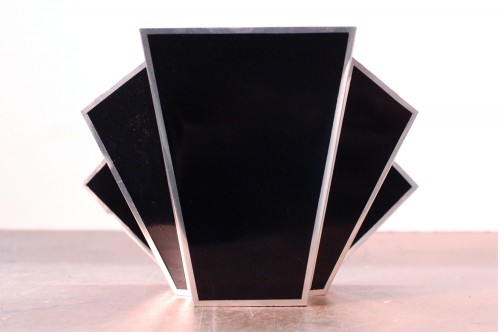

The set for Triad Stage’s And Then There Were None called for a posh, but stark, Art Deco design. One of the key furniture pieces is a liquor cabinet, since each of the ten characters has at least three drinks through the course of the play.

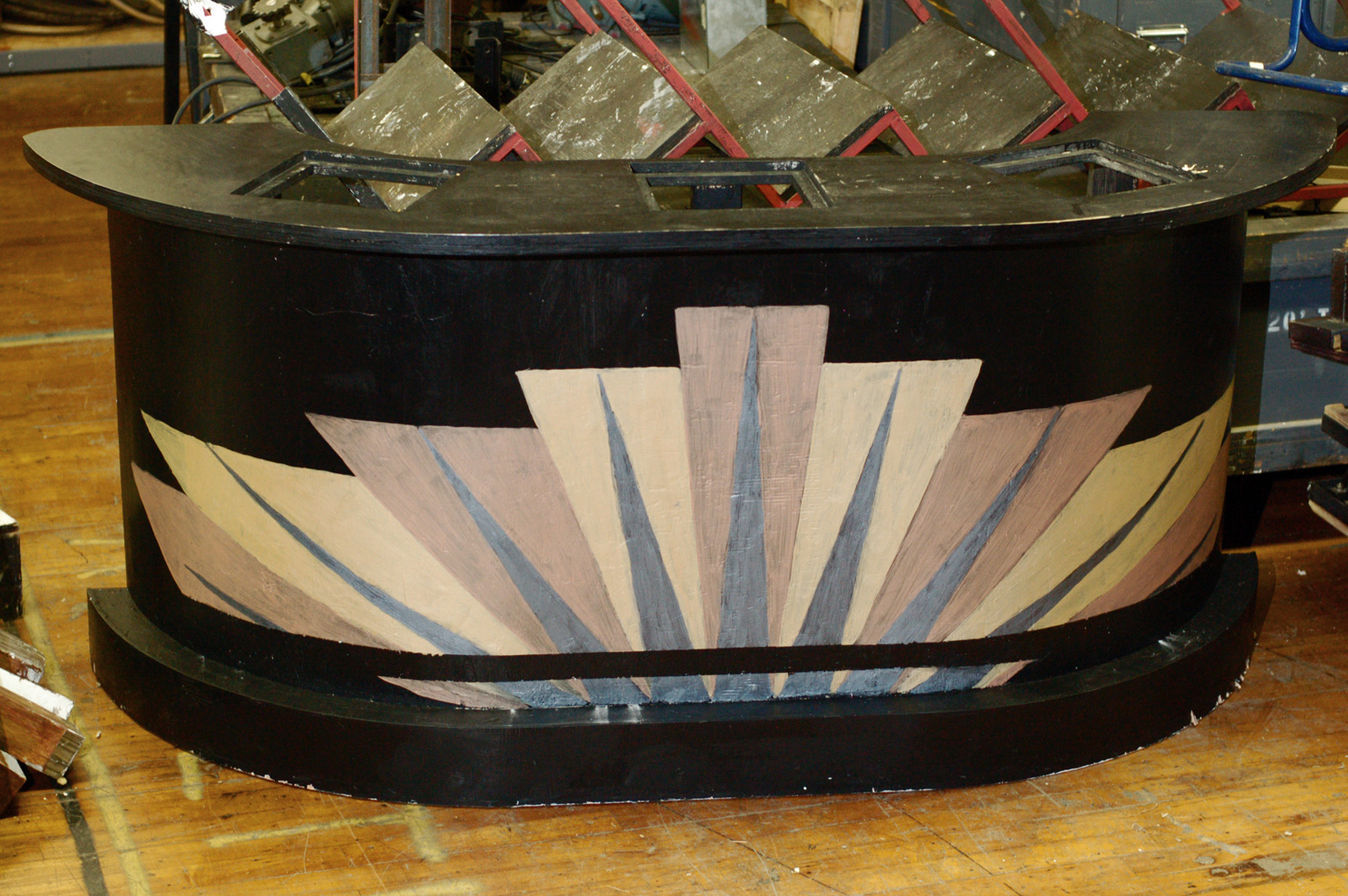

I had no luck sourcing an Art Deco liquor cabinet in this part of the country, so I decided to build it. Having a very distinctly Deco piece on stage would help the other less-distinctly Deco pieces feel at home in the period. Robin Vest (the scenic designer), and I passed around some research images and landed on a piece that had all the right elements but was still achievable with my equipment and time.

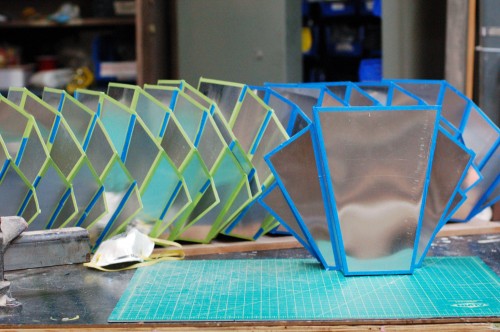

One defining element for this style of furniture is the bold, sweeping curves. These were traditionally made by bending thin sheets of wood and laminating them together to create a curved piece of plywood, then adding a highly-figured veneer on top. That was beyond my budget, but I had previously bent plywood by cutting kerfs, and thought I could do it again. The design of the cabinet was specifically chosen to easily hide the kerf cuts.

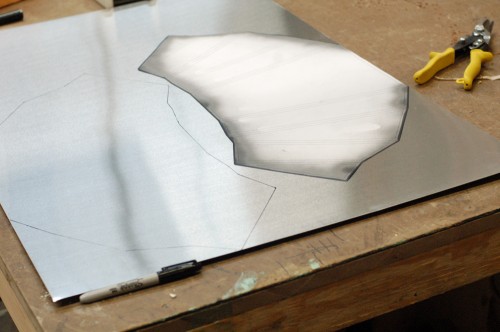

I chose some nice maple plywood from the big box store. The back of the cabinet and the doors would establish the curves, so I taped them together when gang-cutting them on the band saw.

When all the flat, fixed pieces were cut, I assembled it together without glue to make sure everything was measured correctly. The cabinet was basically two parts with a door on each side.

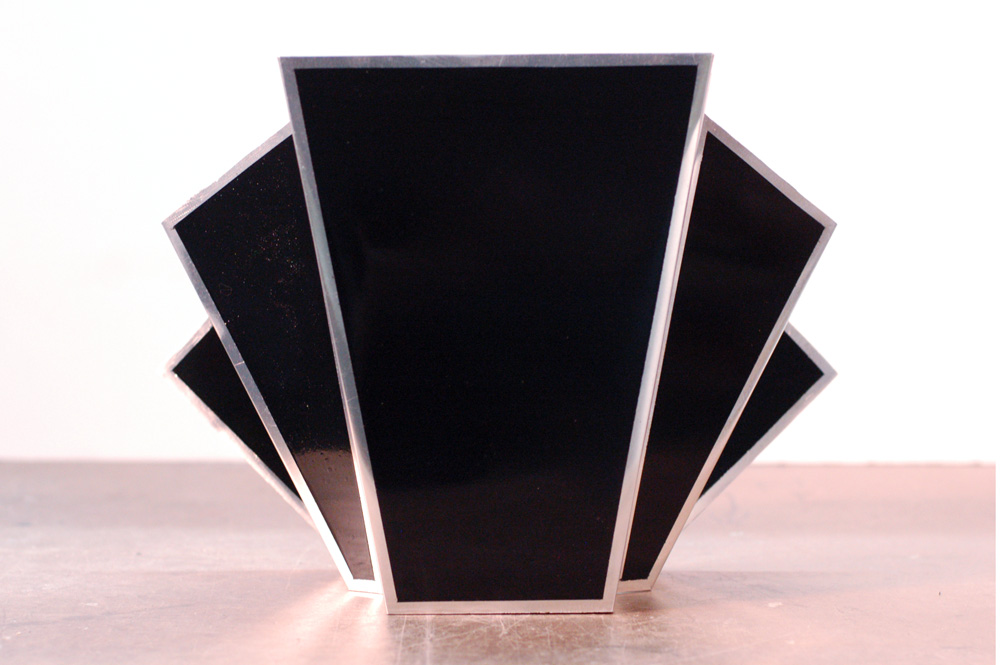

To cut the kerfs, I first measured where the curve would begin and where, roughly, it would end. I left the piece a bit long, intending to trim it to the exact size once the kerfs were all cut. You can never calculate exactly how long a piece should be when you add a curve to it; the material behaves differently than how the math predicts.

I set the blade height on the table saw so it would cut through all but the last layer of ply on my plywood. I used a sled to cross cut the groove through the length of the wood. I had a marking on the table saw so that after each cut, I could slide the wood down to make the next cut, and each cut would be evenly spaced.

I’m sure there is some formula to calculate how far apart each cut should be, but I just used a test piece of wood to make sure I was achieving the curve I needed.

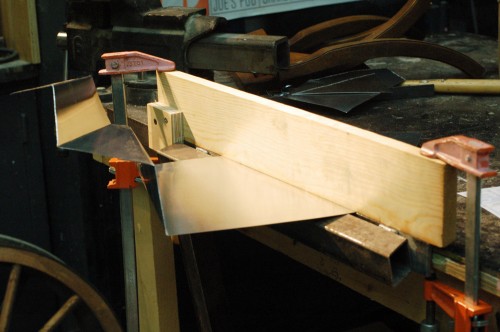

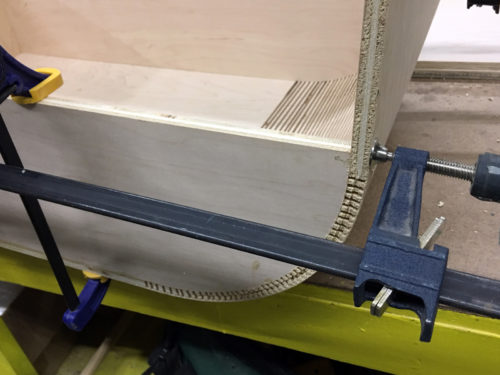

When all the kerfs were cut, I was ready to attach the bent pieces to the frame. They were glued to the back of the cabinet, while the front would be open for the doors. I clamped the doors in place so the plywood was held in the correct shape while the glue dried.

While everything was still clamped, I filled the kerf cuts with a mix of sawdust and wood glue to sort of “lock” it in place. A curved piece of wood like this can move if it is not fully supported.

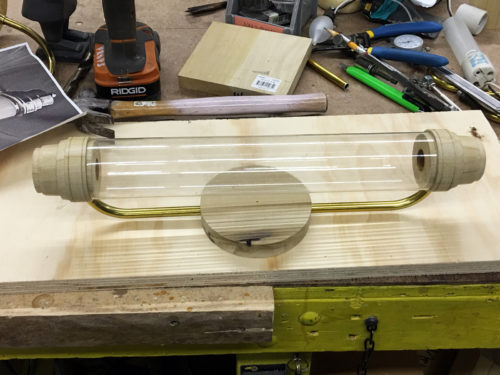

The curved pieces were a bit springy without any front supports, so I added an oak frame. It was inset so the doors would still be flush with the front when mounted; it also helped serve as a door jamb to prevent the doors from swinging inside.

I stained the outside of the cabinet with one coat of English Chestnut stain. All the plywood edges were sanded smooth and filled, then painted black. The curved edges needed a lot of filling to close the gaps from the kerfs. Everything then got two coats of amber shellac, sanded down with some #000 steel wool after each coat.

For the sides of the interior, I laid in some thick mirrored mylar I had left over from another project. A lot of liquor cabinets in this style had mirrored interiors. It also allowed me to cover the kerfs on the inside of the curves, which would have taken forever to sand smooth. The remaining interior surfaces were painted with some bright yellow I had gotten for another 1930s-inspired piece.

I also added some molding to the bottom and two more panels to the top to create the stepped design that is another characteristic of this style.

After mounting the doors, the final step was adding the handles. I cut and shaped some basic handles out of a piece of two-by-four. I added them after the doors were mounted because they all needed to line up visually with each other, even if the doors were not precisely straight and even.

I was very proud of this piece. Even though its flaws and theatrical construction were apparent up close, it looked stunning from only a few feet away.