Every once in awhile, I thought I’d try to look ahead at the future of building props. Prop-making has come a long way in the last few decades, from papier-mache and chicken-wire, to sculpted Styrofoam and CNC-routed parts. Today, I’ll take a peek at desktop fabrication.

Desktop Fabrication

If you need a color copy of a printed page, you can scan it and print it within minutes on the computer which is already in your office. Paper props have become vastly simplified with today’s computer and printing technology, and if your shop has a large color plotter, you can print nearly anything up to four feet wide.

Imagine doing the same with a three-dimensional object. You scan it in, and then “print” an exact copy.

The technology to do that already exists, and has for years, but remains bulky and expensive. Products like the Desktop Factory bring the dream of a desktop factory in every school, business, and home closer to reality.

According to the blog at Ponoko, the Desktop Factory is similar in price to the first consumer laser printer which was released in 1985. If we look ahead, we can see how prices have changed. These days, it can sometimes be cheaper to buy a new printer then new ink! In ten or fifteen years, desktop fabricators can easily cost less than a hundred dollars.

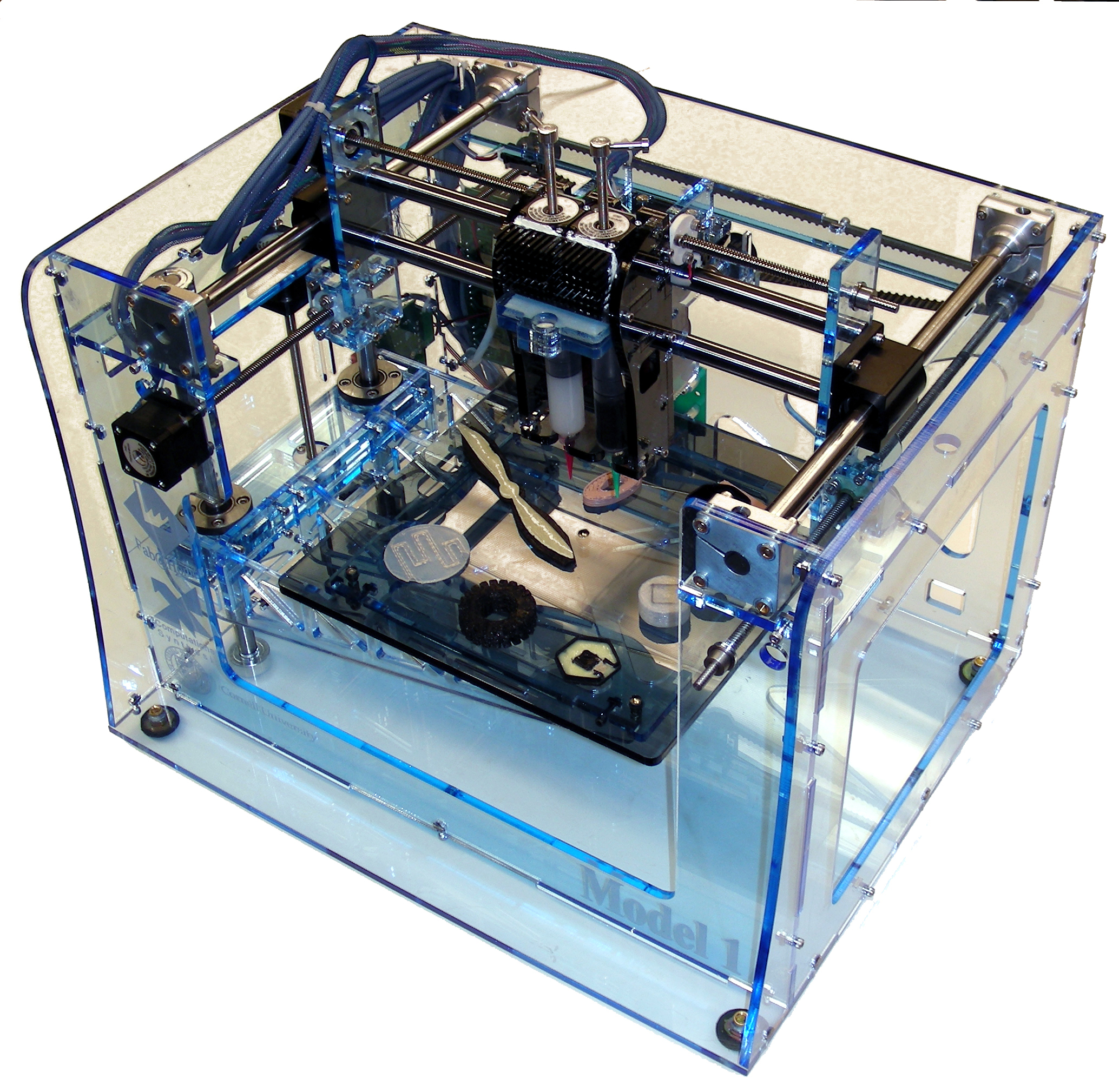

For the truly adventurous, there is a wealth of resources dedicated to constructing your own “fabber”. Fab@Home has everything you need to build and program your own machine to make three-dimensional objects out of a whole range of materials, from plastics to sugar.

When you combine desktop fabrication with more sustainable materials, you get machines like the Matrix 3D Printer, which uses sheets of letter-sized paper to build up a three-dimensional object.

These machines make objects which can be molded and cast, or in some cases, used directly.

I can certainly see more commercial prop shops using these kinds of machines and technologies. For smaller prop shops or university shops, they can still come in handy. Obviously, a desktop model will not let you print out a giant prop. Likewise, if you need a piece of wooden furniture, you can’t use a fragile plastic fabrication, nor would it make sense to cast a piece of furniture in some kind of resin. Additionally, these fabricators would require at least some knowledge of 3D computer programs, such as CAD. While many prop shops have at least one person with a working knowledge of one of the CAD programs, generating a precise drawing of a complicated piece may be too specialized a skill for a five-person shop.

I see the more immediate benefits of a machine like this as a way to make all the “bits and bobbins” that a prop shop is always looking for. Think about the boxes of finials and rosettes we keep around, or the bucket labeled “brass things.” Now imagine building up a virtual library of all of these parts, and whenever you need one, you just print it out. There are many other times when you need some kind of custom shape for a prop where precision is key.

I’m interested to hear how everyone else feels about these possibilities.

**Update**Â The Desktop Factory is no more.