© Michelle Dias

Day 1

May we please have a stool?

Day 2

Thanks for the stool. May we please have a taller stool?

Day 3

Thanks for the taller stool. The director has requested a bench instead.

Day 4

Regarding the bench, would it be possible to put arms and a back on it?

Day 5

Thanks for the sofa. Although the designer would prefer it, the director feels strongly about having the bench back, and altered as requested.

Day 6

After meeting last night with the designer, the director has reconsidered the altered bench and would like to see the sofa again. We appreciate the overtime you put into the bench and apologize for the change.

Day 7

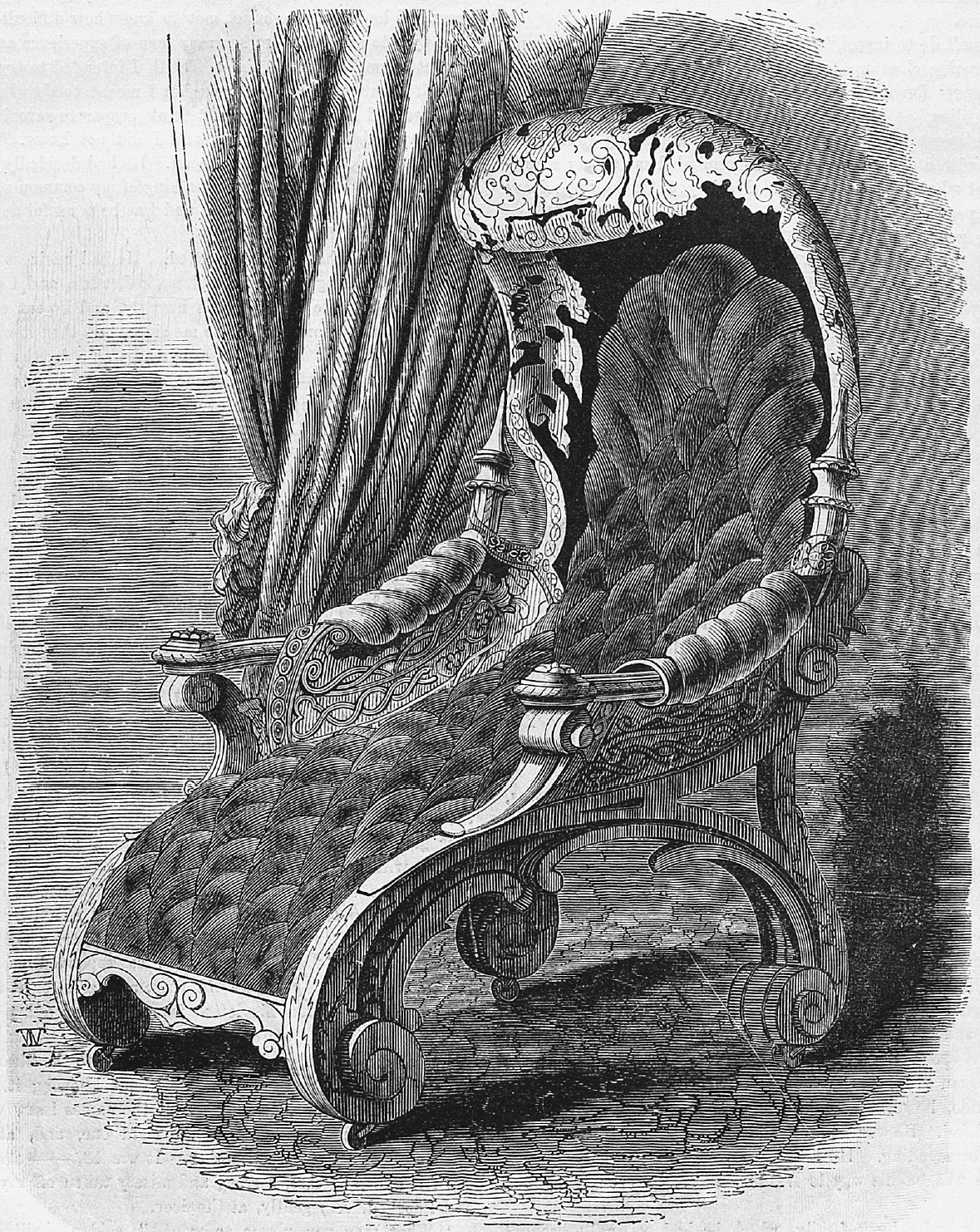

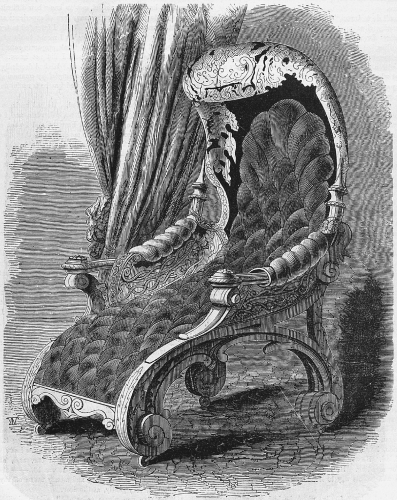

Can we please see all the chaise lounges you have in stock?

Day 8

Thanks for bringing up the chaises. The director has decided to stay with the sofa. Would it be possible to shorten it? To about loveseat size?

Day 9

The director doesn’t care for the style of the loveseat you brought in. We will ask him to discuss it with the designer. Meanwhile, can we pursue our request to have the sofa shortened?

Day 10

Thanks for shortening the sofa. Unfortunately we’ve now found the arms are too low on this one and would like to see all the other sofas and loveseats you have in stock.

Day 11

Can we please have all the sofas and loveseats removed from the rehearsal hall before 10am? The director and designer have met and have decided to try an armchair.

Day 12

Thanks for the armchair. Do you have one with a taller back?

Day 13

Although very nice, the wingback is too tall. Is there an armchair in stock with a back that’s shorter than the wingback but taller than the first armchair?

Day 14

Thanks for the Barcalounger. Wrong style unfortunately, but fun. May we keep it in the Stage Management office? Can we please try again with another armchair?

Day 15

The director loves the new armchair. Thank you.

Day 16

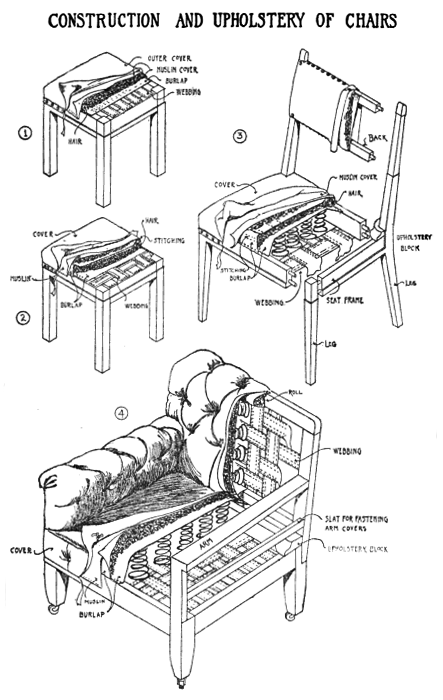

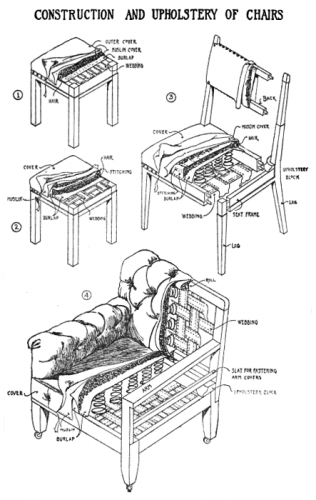

Regarding your note about the designer requesting new fabric for the armchair: we can free up the chair after rehearsal today. It would be great to have it back tomorrow. Is one night enough time for the re-upholstery?

Day 17

After rehearsing with a dining room chair today, the director feels he would like to use that instead of the armchair. Sorry! Hope you didn’t stay too late last night!

Day 18

Do you have another dining room chair that closely matches the one we have, but without arms and with a different fabric? And perhaps a slightly taller back?

Day 19

Thanks for the selection of dining room chairs. If we wanted to use a full set of six, would it be possible to recover the seats before tomorrow’s dry run?

Day 20

We have some news that will make you laugh. The director has decided that one of the plain black orchestra chairs will be perfect. We had one in the rehearsal hall. Thanks and have a great day.

Day 21

Re: the table…

The above was written by Michelle Dias, who passed in 2011. There is a scholarship given in her name if you are interested in knowing more. Thanks to Cindi Zuby for sending this to me and Michelle’s family for allowing me to post it.