I heard a story awhile back from a fellow props artisan. A large company was in town, putting on the kind of show that required hundreds of specialty props, all created specifically for their production. They started out working with one of the larger prop shops in the area. The shop was good, but they were still not happy with a number of the props; the performers themselves needed to talk directly to the artisan in order to give all the details and needs they were looking for. When the prop was finished, they wanted to be able to use it in rehearsal for a bit, then work with the artisan again to suggest changes and ask for modifications.

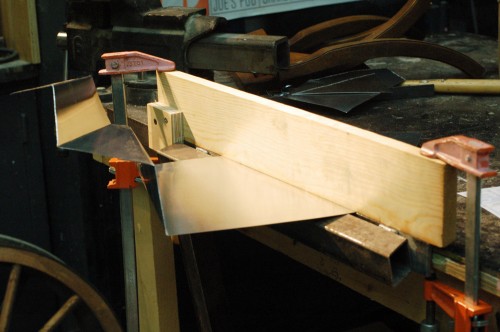

The large prop shop wasn’t set up to do business like this. They were used to taking drawings and draftings from a designer, constructing the prop, and delivering it to the theatre. They could certainly deal with the changes and additions that happen in every production, but the kind of individual one-on-one experimentation with props throughout the rehearsal process that these actors wanted was beyond their capabilities. This is where the fellow props artisan comes in. He was able to provide this kind of daily collaboration. He would talk through the prop with the performer, making notes and asking questions, then head to his shop for the rest of the day. The next morning, he would bring a newly constructed prop to the performer who would try it out and then suggest new changes and additions based on what was learned.

This is the difference between props as a product and as a process, and it is one of the reasons why good props artisans will always be needed. In one case, you are “ordering” a custom prop from a prop shop. In some ways, it is just like you would buy some of your props off of eBay or from a catalog. Having this shop continually make changes and modifications becomes expensive, inconvenient, or even downright impossible. Even if all of the props are built by an outside group, you will still need an artisan on hand who can modify and work with the props to make them do what the show needs them to do. Having an artisan on hand also allows the props department to be a bigger part of the whole collaboration. Like a conductor who lowers the volume of the trumpets or speeds up the tempo at certain parts in the music, an artisan can alter the weight or balance of a prop, change the color, or add a secret handle between rehearsals.

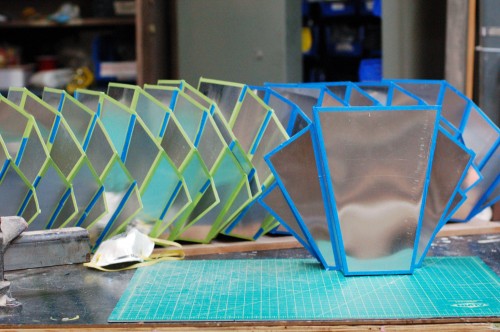

I’m not trying to knock commercial prop shops in this post, but rather make a point about the continuing need for artisans in an age where our industry is seeing more and more computerized fabrication. CNC routers and 3D printers are great technologies, and hold even more promise in the future, but they are no replacement for a good props artisan. They create products. They don’t replace the process.

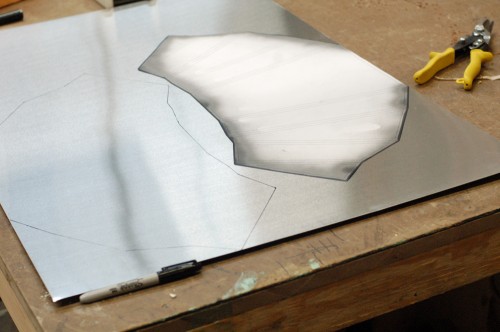

A CNC router can cut an intricate shape out of a piece of plywood with very precise measurements, and it can do it a thousand times with no difference between all the pieces. A props artisan is more than just his ability to cut out a shape drawn on a piece of plywood. A props artisan takes the needs and wants of a prop, balanced with the input of the director, the designer, the actor and the stage manager, and weighs it against the limitations of the theatre, the shop, her skills, and all the resources available to her. She chooses the materials and techniques which best fit all of these requirements to construct the prop. And she does it knowing that it may need to be changed or modified later, or even cut entirely from the show.

A smart props artisan will keep on top of the changes in technology and tools available to him and learn when to integrate them into his process. We’ve integrated computer printers into our manufacturing of paper props. Even with all the amazing things one can do with graphics software, artisans still use a surprising amount of non-computerized techniques to add life to paper props. A good artisan uses all tools and methods available to him rather than altering the prop so it can be manufactured by a certain machine.