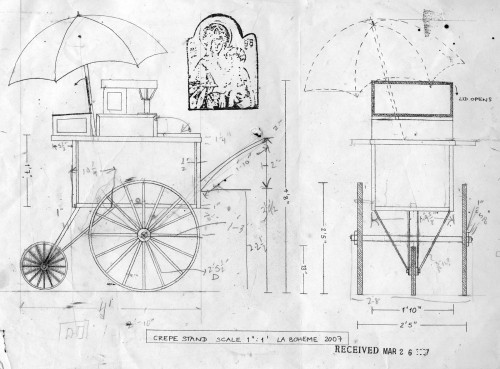

Today I thought I would go retro and show you a cart I built back in 2007. La Boheme at the Santa Fe Opera required a whole bunch of push carts during the outdoor scenes, so the other prop carpenter and I set to work constructing them.

The first one I built was a crepe cart. The structure was simple enough, but the wheels were all custom-sized, so the first thing I had to do was fabricate the wheels and the axle system.

I built the wheels out of metal because the diameter of the spokes and the rim in the drawing was small enough that I was afraid wood might not be strong enough. I TIG welded the rods to the hub to keep the welds as visually-unobtrusive as possible. The rim of the wheel was a length of bar stock bent into a circle and welded together. It also had a strip of rubber glued along the outside to cut down on noise and keep it from tearing up the stage floor.

The front wheel stuck way out to the front of the cart. I first assembled a jig to hold it in position. I then cut the four bars that held it in place and welded them to the axle while the wheel was in position. This ensured that the wheel was centered, at the correct height, and completely parallel with the direction the cart traveled. I thought I was very clever until it came time to remove the jig and I realized I had built the cart around it; I had to cut the jig apart to get it off.

Above is a picture showing the bottom of the cart with the front wheel in place and the axles for the back wheels. If you look close, you can see the back axle is actually separated in the middle; when the cart is turned, the wheel on the inside of the turn spins more slowly than the one on the outside, so they need to be able to spin independently of each other.

I added a circle of wood and a decorative rosette we had in stock to cap off the hub.

The top of the cart was pretty straightforward; it consisted of a plywood box, a thick “counter”, two handles I shaped out of solid alder, and a metal box to serve as the oven. There was also a braking system to lock the wheels in place to keep the cart from rolling into the audience when the artist walked away, but that is a post for another day (In opera, the singers are called “artists”, rather than “actors” or “singers”).

A number of accouterments completed the look. A box with a hinged lid was placed on front for artists to take crepes from. I welded a tube in position to hold an umbrella at a jaunty angle; the umbrella needed to be removable to facillitate storage backstage. Finally, I placed some molding around the edges to match what was in the drawing.

Here is the final cart after the paint shop finished with it and the props master dressed it. Bon appétit!