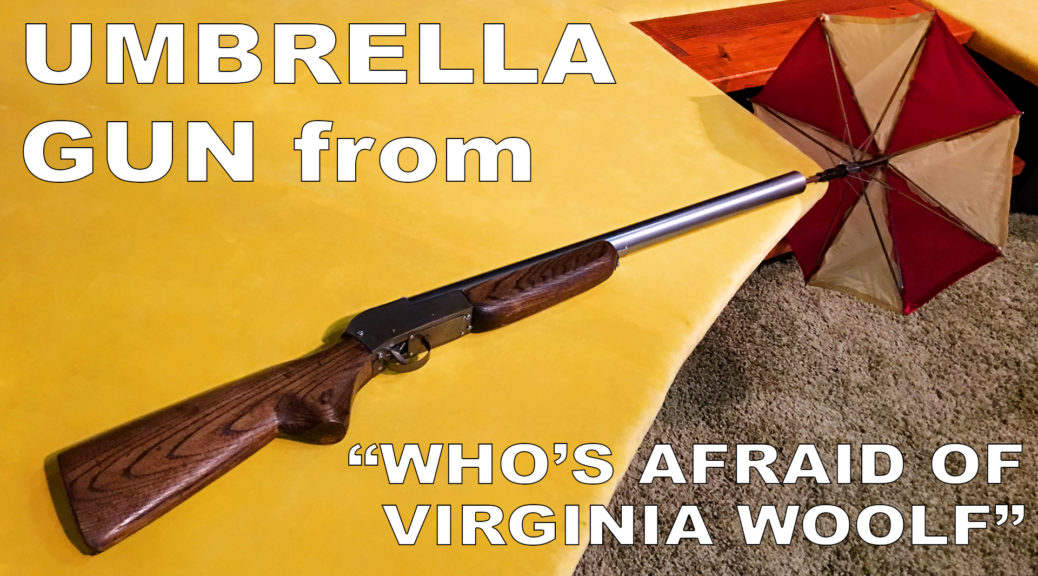

The umbrella gun scene in Who’s Afraid of Virginia Woolf? is one of the most visually memorable in the play. George, tired of his wife Martha’s insults in front of their guests, exits offstage. He sneaks back wielding a shotgun aimed at her head. The guests see him and scream as he pulls the trigger. Instead of the loud report of a bullet, though, a brightly-colored umbrella emerges from the barrel. Hilarious, right?

The original production was written to use a trick umbrella they already had in stock, but every production since has given the props master a headache as they try to figure out the gag. I initially checked with other theaters who had done this show, but theirs had either broken or been disassembled. The rental options out there were either too expensive or looked unrealistic. I decided I needed to build my own.

I needed a pretty thick barrel to fit an umbrella inside. It would look out-of-proportion if I just stuck it on a regular shotgun body. I scaled up the stock and fore-end to cut and shape out of oak.

I bought a chainsaw grinding disc for this project because I had always wanted to try one. It was amazing; it acted like a wood eraser. I just pointed it to the wood I didn’t need and it made it disappear. I will never attempt wood carving without one of these again.

The receiver would need to hold all the parts of the shotgun together and hide all the mechanisms inside of it I cut out several pieces of flat steel stock to weld a hollow container.

With just a welder, angle grinder, and belt sander, I was able to fabricate a decent looking receiver.

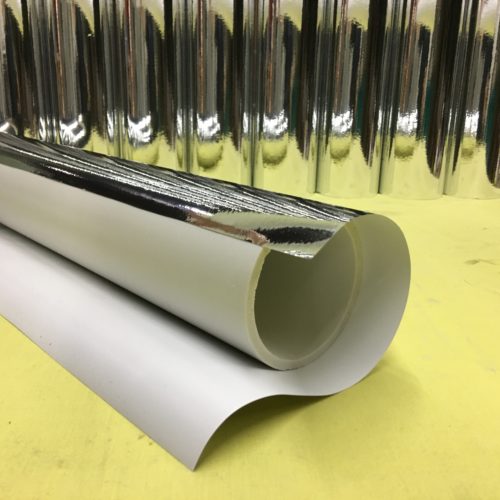

I took an existing umbrella from stock which had its own spring mechanism to make it pop open. I cut off the handle but left the hollow shaft in place. I welded a steel rod to the shotgun that the umbrella could sleeve onto and travel back and forth. To minimize binding, I put a bit of UHMW rod on the end of the umbrella that was slightly smaller than the inner diameter of the copper tube I was using for the barrel. I used copper tube because it was the most rigid tube I could find with the thinnest walls.

I drew up a full scale trigger mechanism in cardstock to figure out what would fit within what I had built. It was just two pieces: a trigger that rotated on a pin, and a long lever with a latch on the end that held the umbrella against a spring until the trigger was pulled. I traced the pieces to steel and cut them out. I slipped a small piece of spring into the fore-end to return the trigger after it is pulled. I slid a long spring over the metal rod in the barrel to actually propel the umbrella after the trigger is pulled.

I painted the barrel to match the receiver and stained the wood pieces darker before sealing them. I coated all the static pieces of interior and exterior steel with shellac to prevent rust. Any pieces of steel which moved against another part was coated with dry lube. I built the gun for easy disassembly in case any future users needed to fix or replace a part.

I have a video which shows all the parts as they are assembled. You can see the various inner mechanisms in more detail if you are interested in how it all works, and if you wanted to see it actually fire.