Remember all those times you’ve had a big upholstery project coming up for a show and you just didn’t know quite where to start? We’ve definitely all been there a time or two.

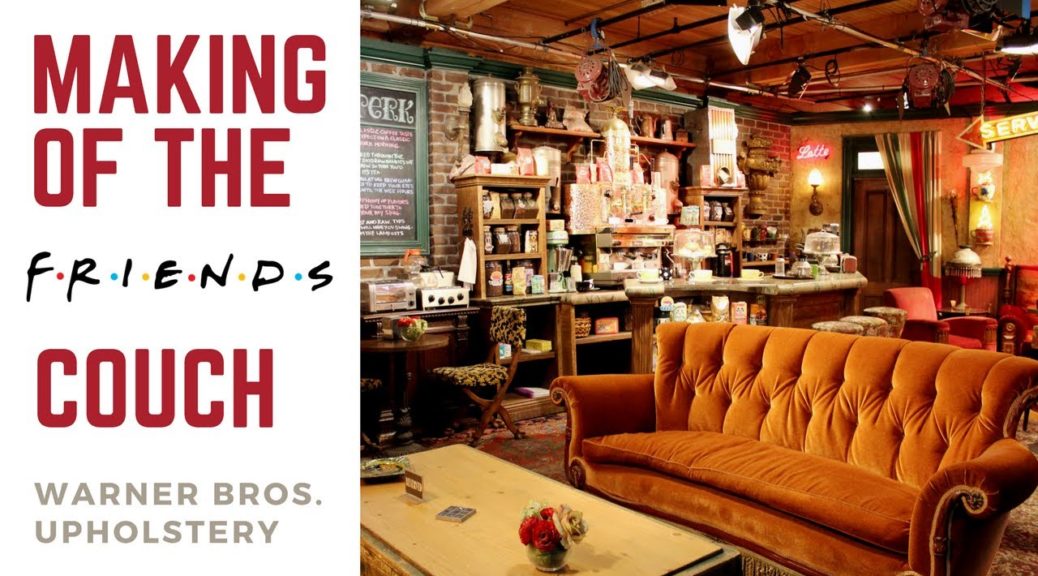

Well we have some great news for you! Because this month S*P*A*M Member Jessica Rosenlieb will join our S*P*A*Minar team to share some great tips and tricks for theatrical upholstery. We’ll take a look at tools of the trade, materials, resources, and the process to tackle your big upholstery projects. This webinar will cover upholstery basics as well as a few advanced techniques will give us some ways to save time and money.

When: Sunday, August 15th at 8pm EST

Where: From the comfort of your home!

REGISTER here: https://bit.ly/TuftingREG

We are once again requesting pay-what-you-can donations to support this S*P*A*Minar programming. All money collected will be used to offset webinar operation costs with additional funds going to our annual grant program for early career prop people. Suggested donation amount is $3.

Donations can be made via PayPal Money Pool here: https://bit.ly/SPAMinarMoneyPool

Registration will remain open until 6pm EST on August 15th and a link to the Zoom S*P*A*Minar session will be sent out to all registered attendees 1 hour before the start of the webinar.

All S*P*A*Minars will be recorded, and the video will be shared to the S*P*A*M YouTube channel the week following the event.