Earlier this year, I was the props master on August Wilson’s Two Trains Running at Triad Stage. The set, designed by Moriah and Isabel Curley-Clay, was a Pittsburgh diner in 1969. Among the various components were thirteen matching diner stools, the kind that spin and are bolted to the floor. It proved impossible to source that many stools within our budget, so I decided to build them.

I designed the main support in two parts: an inner post made of steel that would hold the seat and be bolted to the floor, and an outer post that would sleeve over and appear to be chrome. I welded the inner post out of box tube and quarter-inch plate. I added a small length of pipe to the top so the seat could spin freely.

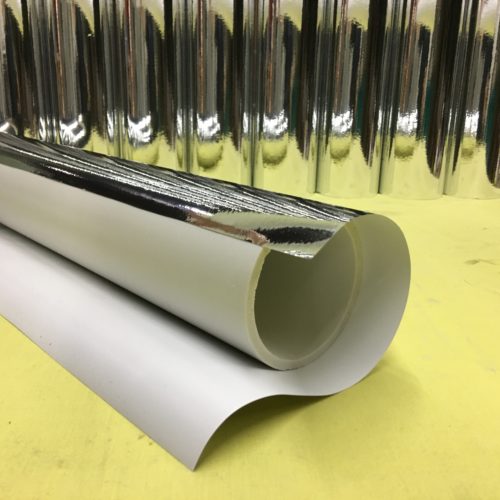

I cut the outer posts out of PVC pipe and wrapped them with silver Mylar.

The flange at the base was a plastic bowl I found. I drilled a hole through it and wrapped it in Mylar as well. The bowl and PVC both slipped right over the steel posts, and I cut some wood spacers to hold them in place.

I built the seat in two parts which could be screwed together after upholstering it. The top part had a block underneath that slipped onto the pipe base and allowed it to spin freely. The side part masked this block and provided a place to attach the vinyl fabric to.

Once upholstered, the seat could slip right onto the steel post. The underside of the seat had a piece of UHMW that the steel rested on, so it could spin with as little friction as possible.

A good portion of the upholstery was accomplished by Keri Dumka, one of my artisans on the show. My apprentice, Victoria Ross, also did some upholstery and aging on these stools.

Here is one of the stools; twelve to go!

Though it was very time-consuming constructing all thirteen of these stools from scratch, the end result was pretty stunning. It looked like we plucked a diner straight from the Hill District and plopped it down in the middle of our theater.